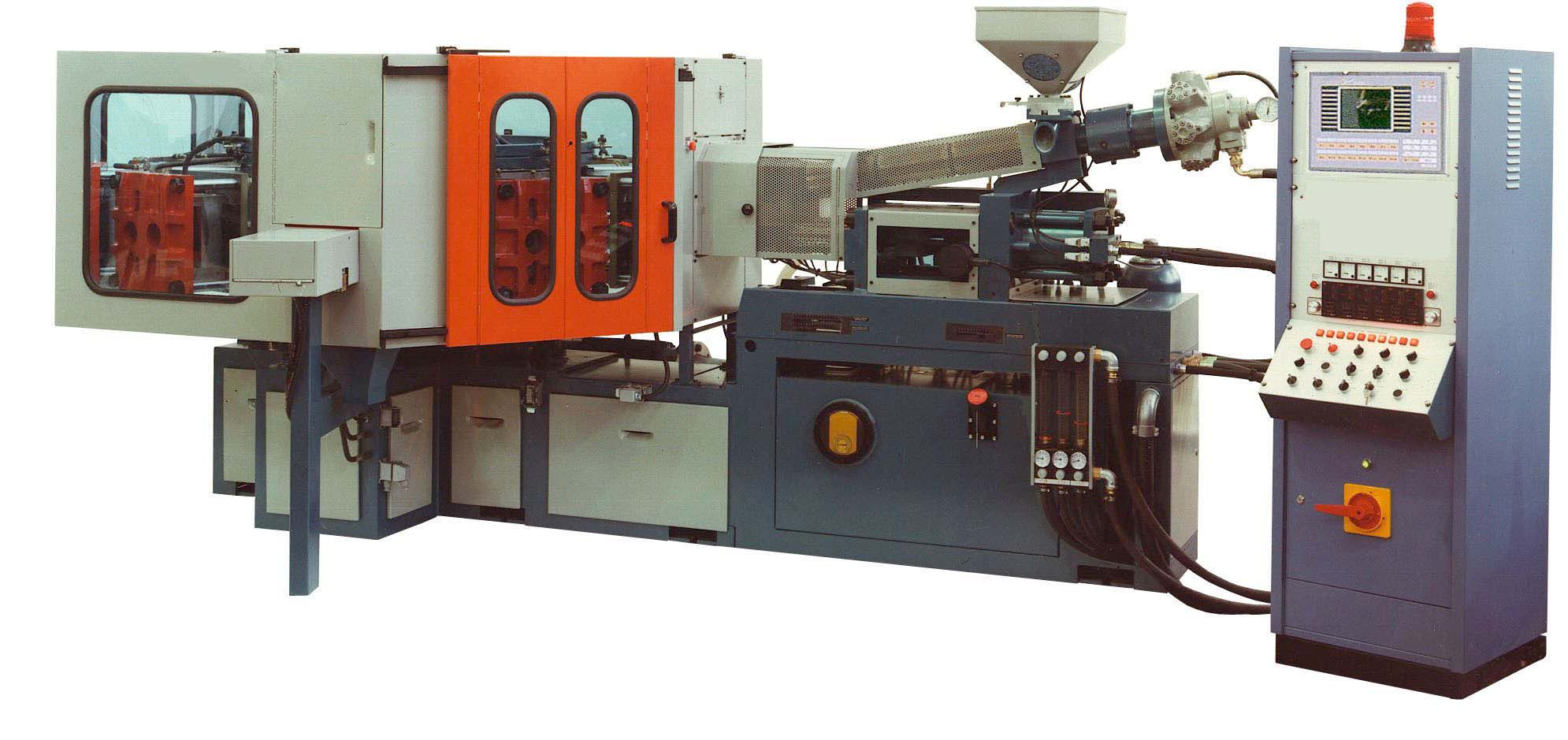

PLASTIBLOCK 10

INSOLES

ROTARY MACHINE FOR MOULDING BLOWN THERMOPLASTIC MATERIALS: PLASTIBLOCK 10

Ten-station rotary machine, for automatic moulding of shoe components (or other products) in blown thermoplastic materials (thermorubber, kraton, E.V.A., styrene, polypropilene, etc.). PLASTIBLOCK 10 is supplied with extrusion screw, its relative expansion chamber and double nozzle head. Machine frames are dimensioned for holding either single or double pair of wedge moulds or one pair of unit moulds, presenting the advantage of speed control of opening stroke and variable intervention of opening itself. For each mould it is possible to control following parameters:

hydraulic pressure and speed times quantity of material to be injected frame regulation

Production:

E.V.A. wedges, 1 pair mould: 150-180 pairs/hour

E.V.A. wedges, double pair mould: 250-300

pairs/hour

E.V.A. units, 1 pair mould: 120-180 pairs/hour

Accessories:

CAROUSEL, round, with 10 stations rotating in synchrony with the machine; in each station is placed one basket for collecting moulded pieces

CONVEYOR BELT for transporting moulded pieces to the carousel

AUTOMATIC FEEDER for plastic material

TECHNICAL DATA

Screw diameter: Ø 60

Injection volume: 1130

Max mould closing power: kg 16000

Ø mould closing piston: mm 125

Max pressure on material: kg/cm2 550

Maximum mould dimensions: mm 290 x 400 x 200

Injection speed: cm3/sec 400/500

Heating power: Watt 13500

Oleodynamic motor couple screw: Kgm 55 a 130 ATM

Pump motor power: HP 15

Table motor power: HP 1,5

Total power installed: kW 25,5

Consumption: kW/h 18

Dimensions: mm 2000 x 2400 x 4200 h