DYMA

SOLES

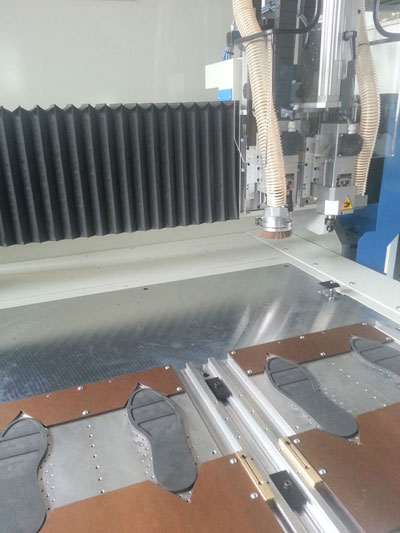

UNIVERSAL WORKING BENCH: DYMA

FUNCTIONAL DESCRIPTION

Dyma_model: Universal Working Bench with working area mm 1000x1000, for sheet cutting of templates and pressers several materials, steel, wood, Bakelite, pvc. It is equipped with nr. two high power electrospindles and with nr. one sheet locking system pneumatic. This model, together with cad system, is ideal for modeling department of a modern sole factory.

Dyma_1.0: Universal Working Bench with working area mm 1000x1000.

It is possible to realize the production of grooves on the soles (in leather and synthetic material) in order to prepare the non-slip injected or applied, decorations, grooves several depth, grooves “3D” on microporous. Important feature of mod. Dyma 1.0 is the possibility to work in “tandem”, that is nr. two soles same size and model simultaneously.

Dyma 1_5: Universal Working Bench with working area mm 1000x1500.

It is possible to realize the production of grooves on the soles (in leather and synthetic material) in order to prepare the non-slip injected or applied, decorations, grooves several depth, grooves “3D” on microporous. The main difference between the machine mod. Dyma 1.5 and the other models on the market are first the possibility to work “in tandem”, that is nr. two soles same size and model simultaneously and second is to have always to disposal the soles working area and templates cutting zone mm 1000 x 1000

Models Dyma 1.0 and Dyma 1.5 can be equipped with the following extra devices, on request:

C: (for machine mod. Dyma 1.0 and Dyma_1.5), with extra device “C axis” able to realize grooves, channels for stitching, decorations, tissue paper cutting for soles with two colors, and so on. The kit is equipped with adjustable heating system, in order to obtain a certain result on leather and synthetic soles

C4 (Dyma 1.0, Dyma 1.5) with extra device “C 4 axis” able to realize nr. 4 different workings on the same sole and to have always at disposal for example nr. 2 wheels and nr. 2 grooves different sizes.

TECHNICAL DATA

Request technical data according to the specific model