Comec SPM12

INSOLES

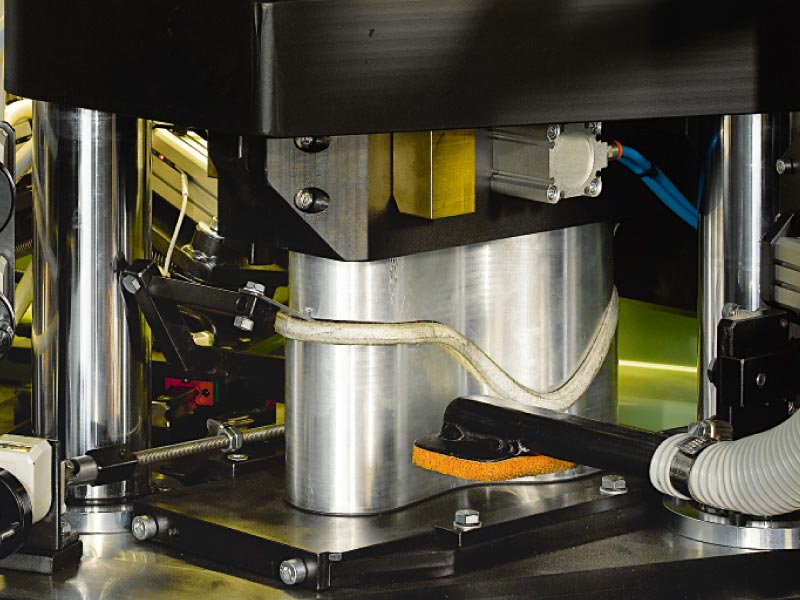

MOULDING MACHINE: SPM12

FUNCTIONAL DESCRIPTION

The semi-automatic moulding machine for insoles mod.SPM12 is a machine to mould each type of insole of any kind of material and is the result of ten years of experience by the moulding machine mod.SP/99. The work cycle is divided in manual loading and automatic unloading. The new system of position of the moulds inclined as to the operator makes easier the access, the visibility, a better safety and the precision in the work operation. The correct placement is guaranteed by two moving lateral stops and one fixed on the heel easily adjustable acting by handwheels with position indicators. The moulding machine mod. SPM12 is composed by number two press groups, right and left, that works alternately: each group is installed on two moving columns that assure the coming down of the male on the female exactly. The pressing is characterized by the special movement of the mould that allows to stop the insole before the moulding allowing an exact precision using the normal moulds (without the stops inside). The turning combination between male and female allow to mould the insole in a progressive way in order to avoid that some wrinkles appear. The oleodynamic part comes directly from the moulding machine mod. SP/99 that during these years has showed a good reliability. The machine is controlled from the operator by touch screen. The electrical part is checked by plc. By safety purpose the machine is equipped by safety photocell to avoid probable intrusion when the moulds go down and push-button panel by two hands for the moulding control. The unloading is automatic and the machine is supplied with two collecting belts for the worked pieces.

TECHNICAL DATA

Dimensions: mm 2180 x 1530 x 2040 h

Maximum hourly pressing: 1200

Pressing Power adjustable up: 40 t

Supplied Voltage: 230/400 V

Absorbed Power: kW 5

Air Consumption: 120 nl/min

Hydraulic circuit tank capacity: 100 lt

Net weight: 1950 kg