Comec SPM15

INSOLES

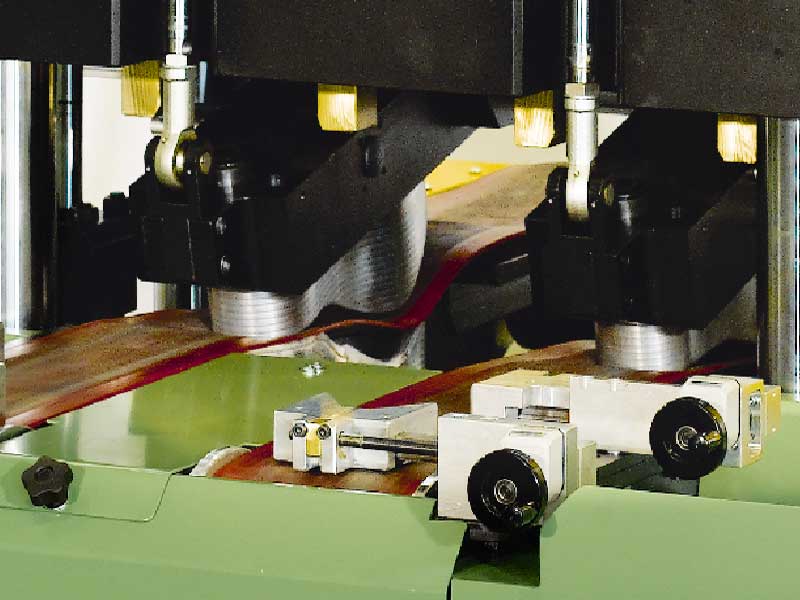

MOULDING MACHINE: SPM15

FUNCTIONAL DESCRIPTION

The semi-automatic universal MOULDING MACHINE mod.SPM/15 is a machine to mould each type of insole of any kind of material. The insoles are placed inside the moulds by two belts motorized by brushless motors whose run is set directly from the controlboard in separated way. The exact position of the insole on the belt by the operator is guaranteed by a lateral stop and another one on the heel easy adjustable acting on handwheel by position indicators. The press group, where the moulds are installed, is supported by four columns that assures the coming down of the male on the female in the exact way. The moulding is characterized by the special movement of the mould that allows to stop the insole using the traditional moulds. The turning combination between male and female allows to mould the insole in a progressive way in order to avoid that some wrinkles appear and in the same time it has the function to stop the insole in the position preset without moving during the moulding. The oleodynamic part comes directly from the moulding machine mod.SP/99 that, during these years, has showed a good reliability. The machine is controlled by the operator by touch screen. The electrical part is checked by PLC. By safety purpose the machine is equipped with safety photocell to avoid probable intrusion when the mould goes down. For the exact position of the first insole the machine is able to mould the insole and take it back to the initial position for the quality check by the operator. So the machine fits well for the preparation of the samples. The moulding run is easy adjustable to increase the productivity.

TECHNICAL DATA

Dimensions: mm 1250 x 1620 x 1790 h

Maximum hourly pressing: 1200

Pressing Power adjustable up: 70 t

Supplied Voltage: 230/400 V

Absorbed Power: kW 5

Air Consumption: 200 nl/min

Hydraulic circuit tank capacity: 100 lt

Net weight: 2300 kg